Zircotec Ceramic Heat Shield Coating - How does it work?

Zircotec Heat Management

Zircotec specialise in the management of heat and are also experts in the plasma spraying process and the production of high performance surface coatings.

Zircotec was formally part of the U.K’s Atomic Energy Authority, being responsible for developing high temperature coatings and thermal barrier processes in the nuclear industries. In 2009, a management buy out turned Zircotec in to an independent limited company based on Oxfordshire.

Today, Zircotec offers one the widest range of ThermoHold based ceramic and metallic coatings that protect against the effects of heat, wear, abrasion and corrosion. Their coatings can be applied to a broad range of differing materials including metals and carbon composites.

Zircotec’s technologies are proven in Formula 1 and professional motorsports and are now found in aerospace, marine, defence, road car and now also industrial applications.

Ceramic Coating - The Process Explained

Zircotec’s ceramic coating service is not a painting service as some people believe. The temperatures involved can reach up to 14,000°C. The spray material is melted in a plasma spray and then applied, travelling at twice the speed of sound.

Plasma Spraying Process

A plasma jet is created by arcing in a plasma gas, creating temperatures well in excess of 10,000°C. The coating material is injected into the plasma stream where it melts and is propelled towards the work piece at around twice the speed of sound. When this material hits the relatively cold substrate it solidifies and in effect ‘welds’ itself in place.

The process takes place in a sealed booth with complex extraction and filtration in place. It is a very power sensitive process leading to Zircotec having their own electrical sub-station.

Preparation

After the part to be coated has been received, it is fully inspected to ensure suitability for coating. It is photographed and logged for full traceability.

The surface is first prepared to clean the substrate and give it a key to enhance adherence of the coating. It removes rust, paint and other previously applied coatings.

Parts are masked by hand or specifically designed tooling to ensure that the coating is only applied to the correct parts. Crucial areas, including bolt holes and fixings are also protected at this stage.

A special ThermoHold bond coat is then selected, dependant upon material and application. This offers better adherence and improved corrosion protection. The bond coat and ThermoHold thermal barrier coating are then applied.

Should a colour be requested, this is then applied. There are over 14 colour options now available.

All parts are sprayed within the Zircotec factory based in Oxfordshire. The turnaround time is normally 10 to 14 days. Some premium faster delivery times are available upon request.

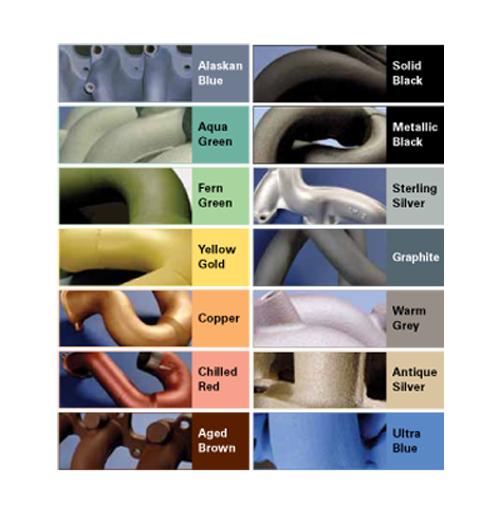

Ceramic Coating Colour Range

Zircotec now offer over 14 different colours for the ceramic coating service. The original and most popular is their Performance White colouring. This double layer coating is guaranteed for applications reaching 1400°C and is ideally suited for use on manifolds, turbos, exhausts and catalytic convertors.

Typical engine compartment temperature reductions of 30°C are possible and some race applications have reported reductions of 50°C. Independent testing by Mira recorded a 33% reduction in surface temperature when compared to an uncoated manifold. Likewise, the significant reduction in the radiant heat which is dissipated through the surface means that other components which are situated near the subject part are more protected from heat damage.

Examples below of a couple of recent coatings we have arranged for our customers -

If White is not your preferred choice, Zircotec offer a range of Performance colours to help compliment most applications. The Performance Colours are a Triple layer coating. The first ThermoHold based bonding coat, then the proprietry ThermoHold based ceramic coat, and finally the colour finishing coat which is incorporated with an outer layer of ceramic.

These Performance Colours offer the same 33% reduction in surface temperatures as the Performance White coating. Likewise, the significant reduction in the radiant heat which is dissipated through the surface means that other components which are situated near the subject part are more protected from heat damage.

Performance Colours are similarly suited for use on manifolds, exhausts, turbos and catalytic convertors. Rated for applications with an exhaust gas temperature of up to 900°C. Performance Colours are guaranteed against faulty materials and workmanship for a period of one year from point of order.